In automotive chassis suspension systems, the control arm (also known as the swing arm or A-arm) is a crucial force transmission hub connecting the wheels and the vehicle body. Like the “limbs” of a vehicle, it silently bears the important mission of ensuring driving safety, precise handling, and ride comfort. While seemingly simple in structure, it directly affects the vehicle’s steering response, road adaptability, and driving stability, making it one of the core components maintaining chassis performance. This article will provide a comprehensive understanding of automotive control arms from the perspectives of function, structure, materials, fault identification, and selection and maintenance.

I. Core Functions: The “Triple Key Roles” in Controlling Driving

The core value of the control arm lies in achieving three core functions through precise connection and transmission, ensuring stable vehicle operation under complex road conditions:

First, load transfer. As the “load-bearing bridge” of the chassis, the control arm must efficiently transmit various forces borne by the wheels to the vehicle body, including the vertical weight of the vehicle, the lateral centrifugal force during cornering, and the longitudinal acceleration and braking forces. Simultaneously, it can work with the suspension system to buffer road impacts, reducing the transmission of vibrations to the passenger compartment.

Second, wheel guidance. Through the elastic connection of ball joints or bushings, the control arm fixes the relative position of the wheel and the frame, limiting irregular longitudinal and lateral wheel movement and ensuring that the tires always travel at a preset camber and toe-in value. This function is crucial for precise vehicle steering, preventing veering and fishtailing.

Finally, there is the dynamic adjustment function. Utilizing the articulated structure of the ball joint, the control arm allows the suspension system to perform precise geometric movements on bumpy roads, always maximizing the tire’s contact patch, thereby improving vehicle grip, making driving more stable, and braking more reliable.

II. Mainstream Types and Structures: “Dedicated Designs” Adapted to Different Suspensions

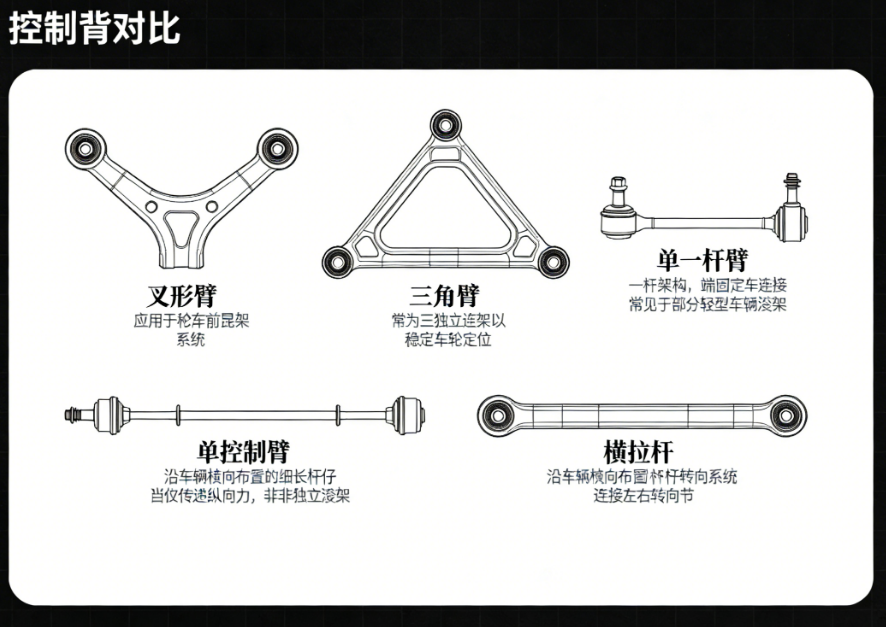

The structure of the control arm must match the vehicle’s suspension system. Different types of control arms differ in their functional focus and application scenarios. Common types mainly include:

- Fork (V) Arm: Mostly used in the upper and lower arms of double wishbone independent suspensions or the lower arm of MacPherson strut suspensions. The fork-shaped structure effectively transmits lateral loads, providing strong lateral support and minimizing deformation during cornering, ensuring steering precision.

- Triangular Arm: Widely used in front MacPherson strut suspensions, this lower arm simultaneously transmits lateral and longitudinal loads, controlling the relative movement of the wheels and the vehicle body. It’s a classic design that balances load-bearing and steering.

- Single Control Arm: Primarily used in multi-link suspensions, usually two are used together. They can transmit lateral and longitudinal loads separately, improving the precision of wheel movement through multi-dimensional constraints, thus optimizing ride comfort and stability.

- Tie Rods and Transverse Tie Rods: Tie rods are often used in trailing arm suspensions, primarily transmitting traction and braking forces; transverse tie rods are commonly found in multi-link suspensions and steering systems, focusing on bearing lateral loads and guiding the wheels.

Structurally, the core of a control arm consists of the arm body, bushings, and ball joints. The arm body is the core load-bearing component, with its two ends connected by bushings (connecting to the vehicle body) and ball joints (connecting to the wheels). Bushings absorb vibrations and reduce noise, while ball joints ensure flexible wheel rotation; the performance of both directly affects the overall performance of the control arm.

III. Material Differences: A Trade-off Between Performance and Cost

The material of the control arm directly determines its strength, weight, and service life. Currently, the mainstream materials are steel and aluminum alloy, with some high-end models also using magnesium alloy. Each has its advantages and disadvantages:

- Steel (including cast iron): Lower cost, effectively controlling overall vehicle cost, hence its highest market usage. Steel control arms offer excellent strength and rigidity, able to withstand repeated impacts, suitable for heavy vehicles or cost-sensitive family cars. However, its weight is greater, increasing unsprung mass and affecting suspension response and fuel economy to some extent.

- Aluminum Alloy: In line with the trend of lightweight automotive design, its weight is significantly lighter than steel, significantly reducing unsprung mass and improving suspension response, handling performance, and fuel economy. Aluminum alloy also has good corrosion resistance and heat dissipation, suitable for rainy and salty climates. However, aluminum alloy has higher manufacturing and maintenance costs, and is mostly used in mid-to-high-end performance models, such as the Audi Q5L’s lower control arm, which uses aluminum alloy.

- Magnesium Alloy: Lighter and stronger, it’s the ultimate choice for lightweighting, but due to its high price, it’s only used in a few high-end luxury models or performance cars.

IV. Fault Identification: These Signals Indicate “Control Arm Needs Inspection”

Control arms bear complex mechanical loads over long periods, making them prone to wear, deformation, and other faults. When a vehicle exhibits the following symptoms, it needs immediate inspection:

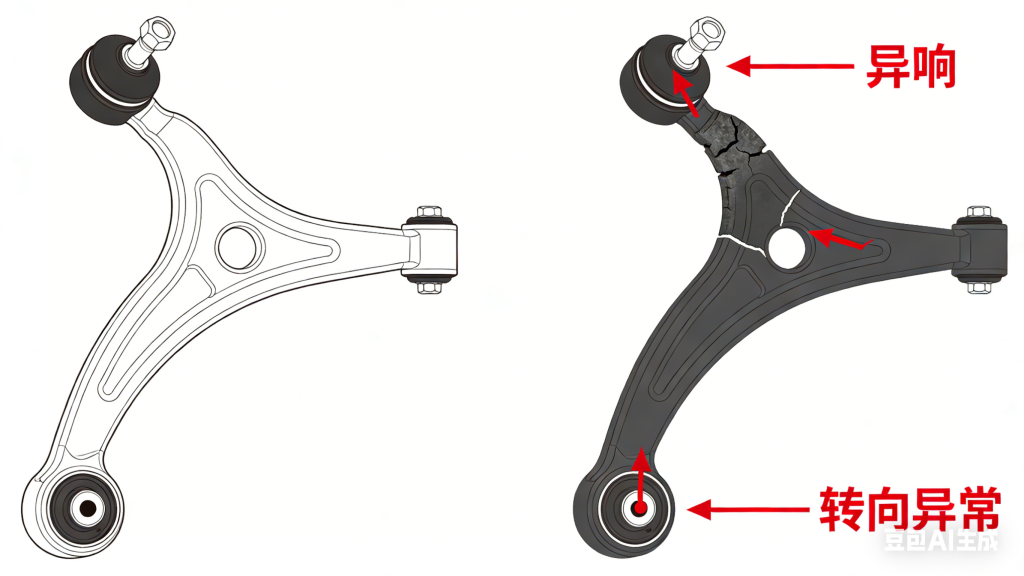

- Abnormal Noises: “Clunking” or “creaking” noises when steering or driving over bumpy roads are often caused by worn or damaged bushings or loose ball joints. In these cases, vibrations cannot be effectively absorbed, resulting in impact or friction noise.

- Abnormal Steering: Noticeable steering wheel vibration, increased steering play, or vehicle pulling to one side or steering delay may indicate control arm deformation or ball joint wear, leading to deviations in wheel alignment parameters.

- Abnormal Tire Wear: Unilateral tire wear or serrated wear is highly likely due to a control arm malfunction causing inaccurate wheel alignment and uneven tire stress.

- Sluggish Suspension Response: After traversing uneven surfaces, the vehicle body sways and fails to recover quickly, or the wheels bounce frequently, indicating that the control arms are unable to properly restrain wheel movement, affecting the dynamic adjustment function of the suspension.

V. Selection and Maintenance: Key Points to Extend Lifespan

The selection and routine maintenance of control arms directly affect driving safety and operating costs. The following aspects require special attention:

Selection Points

- Matching Vehicle Model: Prioritize control arms that perfectly match the original vehicle’s specifications and model to avoid affecting suspension geometry parameters due to dimensional deviations.

- Preferred Brands: Well-known brands such as Delphi and Owl have deep technological expertise and offer more reliable product quality; for emerging brands, focus on cost-effectiveness and user reviews, choosing reliable products within your budget.

- Inspect core components: The ball joint should be firm and require considerable force to bend; a loose ball joint of inferior quality will result in poor driving feel. The bushing should be made of high-quality rubber with a matte finish, a waxy sheen, and a non-pungent odor. It should have good sealing properties and be resistant to damage. Avoid choosing shiny, pungent, inferior synthetic rubber bushings.

- Suitability requirements: For those prioritizing handling and fuel economy with a sufficient budget, aluminum alloy is an option; for those focusing on cost control, steel control arms are a more practical choice.

Maintenance Points

VI. Summary: The Indispensable “Chassis Safety Guardian”

As a core force-transmitting and guiding component of the automotive suspension system, the control arm, though inconspicuous, directly determines the vehicle’s handling, comfort, and driving safety. From material selection to structural design, it must balance strength and flexibility; from routine maintenance to fault replacement, every aspect is crucial. Understanding the relevant knowledge of control arms and paying timely attention to their working status are essential to ensuring the vehicle maintains good driving performance and building a solid safety barrier for every journey.