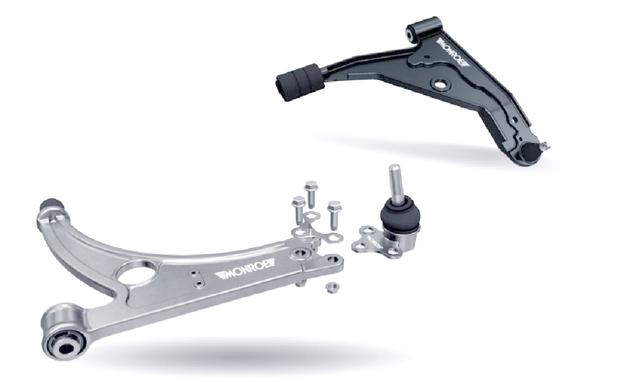

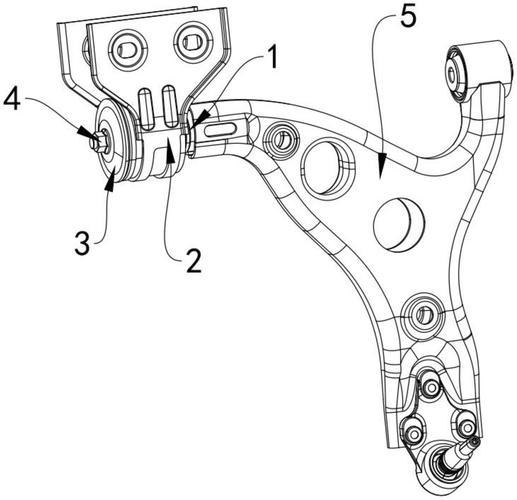

The suspension system, a critical automotive system comprised of precision components such as control arms, suspension ball joints, tie rod ball joints, and stabilizer links, plays a crucial role in a vehicle’s ride smoothness and handling stability. As a core component, the control arm not only guides the movement of the wheels but also efficiently transmits various forces acting on the wheels to the vehicle body.

Next, we’ll delve into how to properly install these suspension components to ensure your vehicle’s safety and performance. This “Micro-Lesson” will focus on the control arm replacement process, providing expert guidance for maintaining your vehicle.

▣ Removing the Old Control Arm

Lift the vehicle and remove the tire on the damaged side of the control arm.

Loosen the screws securing the suspension ball joint to the steering knuckle.

Use a special tool to pull the ball joint out of its mounting hole.

Use a pry bar to push down on the control arm to release the ball joint from the steering knuckle.

Loosen all screws securing the control arm to the chassis.

Remove the old control arm from the vehicle.

▣ Installing a New Control Arm

Before installing the new control arm, confirm that it matches the vehicle being repaired.

Reverse the installation steps, first securing the control arm to the chassis, then tightening the ball nut.

Use a hydraulic jack to compress the suspension. Ensure the screws securing the control arm to the wheel assembly are tightened to the vehicle manufacturer’s specified torque.

▣ Post-Installation Inspection

After completing the repair, be sure to check and adjust all angles of the steering system to ensure the safety and performance of the vehicle.